A need for custom and standard, high-density power supplies

When a deadline is looming and you need to quickly and reliably design, prototype and deploy a custom power supply into your system, let Vicor Power Systems implement an efficient, power-dense and reliable solution. To meet today’s demanding customer requirements, Vicor Power Systems offers more than just custom design capability. Our engineers will work closely with you during the full process from definition and design through manufacturing to ensure you get the most efficient and flexible power supply from source to point-of-load.

AC-DC and DC-DC designs incorporating multiple outputs

AC-DC and DC-DC designs incorporating multiple outputs

Our dedicated team of engineering and manufacturing professionals understand industrial markets and the types of electronic and electro/mechanical equipment used. They work with you to help solidify your requirements and to provide rapid concepts and prototypes that that leverage Vicor high-performance modules for optimal systems capability. The team also consists of project managers who develop and monitor integrated project schedules and host design/manufacturing/ test readiness reviews. This team understands unique, cutting-edge technology and is able to utilize the full resource of Vicor manufacturing, process and design engineering. We engineer AC-DC and DC-DC ultra-high power systems that include multiple outputs. Solutions maximize efficiency and cost-effectiveness, and they reduce time to market for both custom and standard power systems.

A team dedicated to optimal system performance

A team dedicated to optimal system performance

Decades of experience

In-house mechanical design expertise

Leveraging high performance Vicor modules

System power levels from 100W to Megawatts

Benefits of working with Vicor Power Systems

Benefits of working with Vicor Power Systems

Facility UL and TÜV certified

Rapid concept definition and prototyping

Efficient, power-dense and reliable solutions

Rugged custom and industry standard ATX power systems

Turnkey power system examples

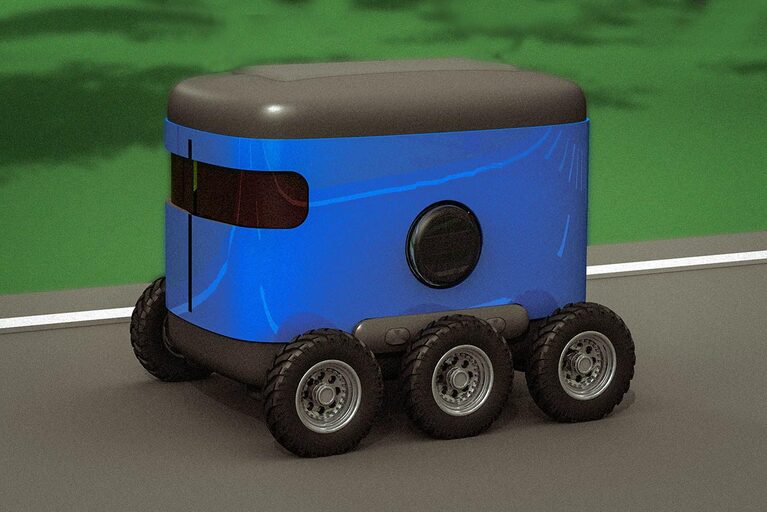

Autonomous AI vehicle

Autonomous vehicles are requiring higher power, higher efficiency, small size and more dense power conversion products in order to drive multiple sensors and computer cards. Standard ATX supplies no longer meet these new higher power requirements and consume increasingly valuable payload space.

The Vicor PRM/VTM combination provided the regulation and isolation from the onboard battery in order to deliver the required sensor voltages. This solution also met the high-efficiency requirements in order to conserve battery life for longer operation in the field.

High-power LED lighting

As LED displays become the size of buildings, the power challenges multiply and require innovative solutions. Being able to convert 480VAC 3-phase coming into the building directly down to the LED panels with a single supply simplifies the power architecture and allows for more complex lighting designs.

In order to deliver enough power to run large panels of LEDs efficiently, this supply takes in the 480VAC 3-phase line, rectifies it, then using advanced ultra-high voltage BCM bus converters and PRM regulators, provides multiple 52V outputs to power the various loads in an extremely dense package.

Electric vehicle charging

Electric vehicles in the future will need to be able to accept different voltage chargers in order to meet their specific battery charging requirements. 800VDC batteries are being considered in future vehicles, and in order to charge them from the existing 400V infrastructure, an up-converter is required.

The application requires a highly efficient step-up converter that will double the charging voltage without interfering with charging current control. Using 2:1 fixed ratio NBM bus converter modules that can reach 98% efficiency, a compact, lightweight power supply unit was developed that is able to seamlessly step up the standard charging voltage to the required 800V.

Tethered surveillance drone

As payloads and UAV power requirements increase, the only way to deliver enough power efficiently up the tether is with a higher voltage DC source on the ground. This high voltage, low current solution reduces the diameter, weight, drag and line losses of the tether.

In order to deliver enough power to the drone, 3-phase power is converted to high-voltage DC. This VPS solution delivers 8kW up the tether and has the unique ability to produce “extra voltage” as the current demand increases compensating for tether losses maintaining regulation at the UAV. The use of high voltage BCM6123 isolated DC-DC converters in a stacked configuration enables a tether voltage of up to 800V.