優化 DC-DC 轉換器穩定性:源阻抗效應的 AC 與瞬態模擬分析

探討如何通過頻域 AC 小訊號分析和時域瞬態分析來優化 DC‑DC 轉換器的穩定性

21 世紀,電力需求急劇增長。工業設施、機器人、輕型電動汽車、無人駕駛車、太陽能系統以及自動測試設備等各種應用都需要更多電力。本文將探討為何過渡到 48V 配電系統比重新設計傳統的 12V 系統更具優勢。

隨著汽車向電動汽車(EV)平臺的轉型,尺寸、重量和功率密度成為關鍵因素。例如,800V 牽引電機逆變器中的大容量負載需要專用預充電電路以避免損壞性湧流。Vicor 固定比轉換器擴充了設計可能性,其預充電支持能力優於其他供電網路。

數十年來,12VDC 母線一直是工程師們的可靠選擇,已成為電池供電與 AC 線路供電設計的實際標準。這種廣泛應用在很大程度上歸功於 20 世紀 50 年代汽車行業採用的六芯 12.6V 鉛酸電池,這推動了高量產、低成本和廣泛的可用性。

然而,進入 21 世紀後,由於系統目標日益宏大,電力需求呈現爆發式增長。工業設施、機器人、輕型電動汽車、無人駕駛車、太陽能系統以及自動測試設備等各種應用都需要更多電力。

因此,12V 電源能够向負載高效輸送的電量已達到實際極限,難以滿足現需求。 由於電流增大,佈線中的電阻(IR)損耗導致電源與負載之間產生過大壓降,而 I²R 功率耗散不僅浪費電量,更會加劇散熱挑戰。 這些壓降和功率耗散是由物理定律制約的現象,無法避免。

迄今為止,解决這一困境的方案一直都是採用更粗的線纜和連接器。 然而,這種方法會帶來線纜重量新增、佈線方案受限以及連接器成本上升等問題。因此,對多數應用場景而言,這種方案已不再適用。

本文闡述了相較於重新設計傳統的 12V 系統,過渡到 48V 配電系統更能滿足當今電子設備日益增長的電力需求。此外,我們還詳細解析了雙向橋接轉換器解決方案如何助力設計人員實現 12V 轉 48VDC 電源的平穩過渡。

考慮到陞級甚至重新設計 12V 系統的局限性,提升母線電壓才是更優解,而 48V 系統是理想的選擇,原因如下:

電力優勢顯而易見。在相同功率水准和現有電纜條件下,48V 系統的電流僅為 12V 系統的四分之一,因此電阻損耗降低了 75%。此外,還可以使用更細的線纜,同時將損耗控制在可接受的範圍內。從功率角度看,如果使用原有線纜,線纜損耗可降至原先的十六分之一; 而採用更細的線纜也能將功耗和自發熱控制在更低水準。

然而,設計系統時強制完全切換到 48V 並不現實。 現有的傳統 12VDC 電源、負載及組件數量龐大,無法放弃,也不應該輕易放弃。真正的挑戰在於如何實現平滑過渡——既能利用傳統 12V 母線創建新型 48V 母線,也能讓新型 48V 電子設備為傳統 12V 系統供電。

在許多設計方案中,既有傳統 12V 系統,也有新型 48V 系統,這就需要在兩種電壓之間實現高效率、高密度的轉換。值得慶倖的是,Vicor 推出的電源模組可完美橋接 48V 與 12V 電源母線。

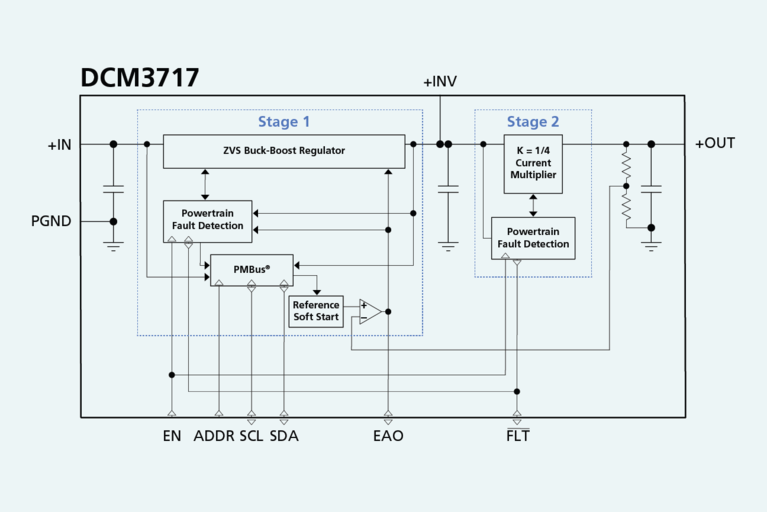

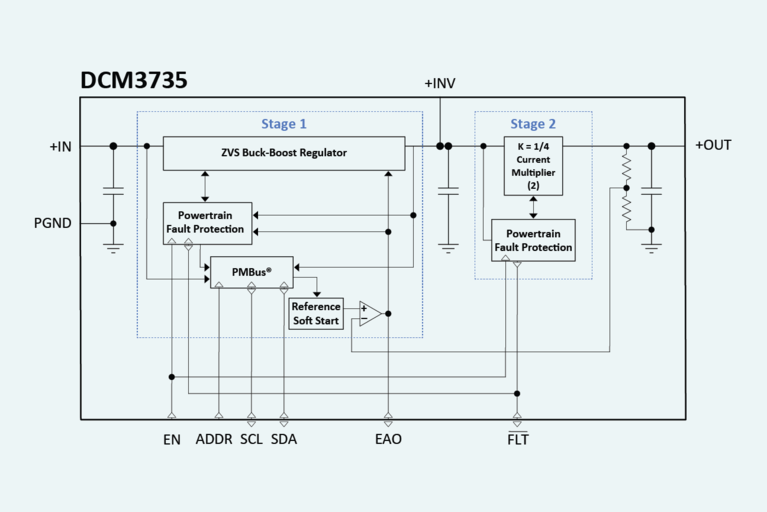

越來越多的應用採用 48V 母線架構,Vicor 48V 轉 12V DC-DC 轉換器為傳統 12V 系統的相容與協同運行提供了簡便的解決方案。例如,連續功率為 1000W 的 DCM3717 及相似的連續功率為 2000W 的 DCM3735 採用的工作輸入電壓為 40VDC 至 60VDC,可生成 12V 穩壓輸出電壓,而電壓調節範圍為 10V 至 12.5V(如圖 1 所示)。這些模组最多可並聯四個,以支持更高的功率水准。 這些非隔離模組還集成了 PMBus® 介面,用於控制與遙測。

圖 1:1000W 的 DCM3717(右)與 2000W 的 DCM3735(左)是緊湊、高效的 48V 轉 12V 降壓非隔離 DC-DC 轉換器。

這些模組採用的精密設計僅需少量外部組件,就可顯著提升板級功率密度(如圖 2 所示)。它們的開關頻率超過 1MHz 時,峰值效率高達 96%,這充分表明其對系統熱負荷影響極低。這些轉換器既可獨立使用,也可與下游負載點(PoL)產品配合使用,以支持高效的配電網路。

圖 2:DCM3717 與 DCM3735 的高度集成極大降低了設計挑戰與潜在問題。

這種表面貼裝(SM-ChiP ™) 轉換器採用電鍍覆膜封裝,使其結構遠比分立式解決方案更加緊湊(如圖 3 所示)。 資料說明了一切:1000W 的 DCM3717 其具體尺寸為僅 36.7mm×17.3mm×5.2mm,而 2000W 的 DCM3735 為 36.7mm×35.4mm×5.2mm。儘管體積小巧,這些封裝仍具有出色的散熱效能,散熱均勻且可預測,因為封裝的上下表面熱阻抗較低,便於熱管理。

圖 3:與分立式方案(左)相比, SM-ChiP™ 實施方案(右)可實現更加緊湊的板級電源解決方案。

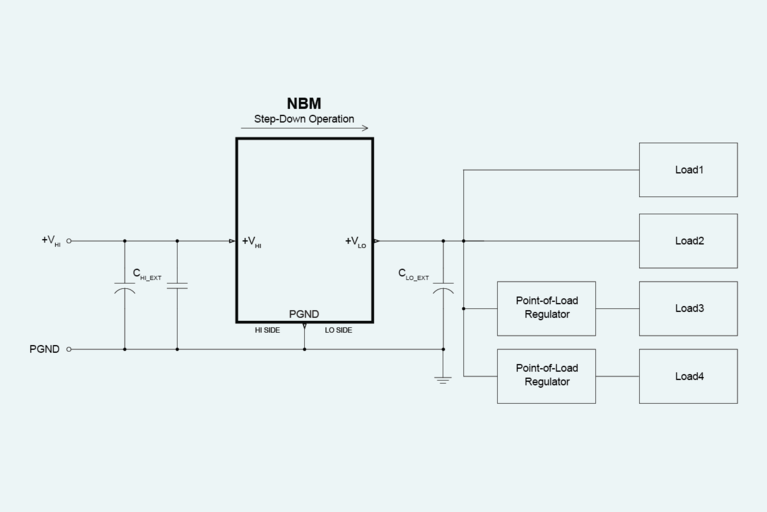

為了支持互補的升壓路徑,Vicor 推出 NBM2317——一款工作頻率達 1.7MHz 的雙向 12V/48V DC-DC 轉換器,可為新舊母線電壓的新舊系統搭建橋樑。在降壓模式下,它支持 40V 至 60V 高壓側母線輸入,可生成 10V 至 15V 按比例調節的低壓側輸出(如圖 4 所示)。這種設計既能相容傳統硬體,也支持現時僅提供 12V 版本的眾多組件。

圖 4:NBM2317 雙向 DC-DC 轉換器可將標稱 48V 電源軌降壓至 12V,以支持傳統組件。

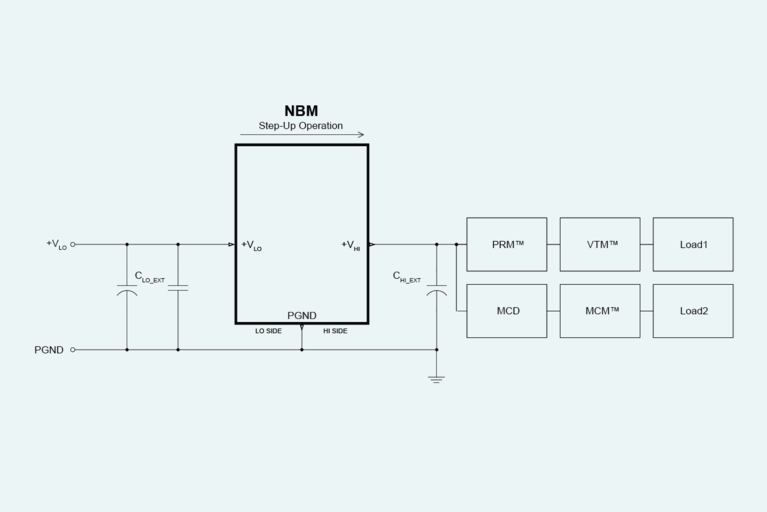

同一模組還可用於升壓模式,能够將傳統 12V 母線提升至 48V 母線,從而為低壓母線系統中的新硬體供電(如圖 5 所示)。

圖 5:NBM2317 雙向 DC-DC 轉換器亦可實現 12V 轉 48V 的升壓轉換,直接為 48V 電源軌及其他局部 DC-DC 轉換器供電。

SM-ChiP™ 板載封裝技術可提供高密度、高效率、低成本的解決方案,以應對新舊母線電壓挑戰。 其尺寸僅為 23mm × 17mm × 5.2mm,占板面積只有傳統低頻(低於 1MHz)轉換器的一小部分。

這款非隔離型橋接轉換器可提供 1000W 連續功率與 1.5kW 峰值功率,在 800W 負載時峰值效率達 97.9%。 其額定輸出電流(降壓模式)為 60A 連續電流與 100A 瞬態電流(持續 2ms),而升壓模式對應值為 15A 連續電流與 25A 瞬態電流。內寘濾波功能無需外接組件即可實現低雜訊輸出,對負載端瞬態的回應時間低於 1μs,同時將輸出電壓穩定維持在較窄的電壓範圍內。

從傳統 12V 設計轉向 48VDC 配電網路的理由令人信服。這樣做可以有效解決能效提升、線纜尺寸與管理優化以及損耗控制等日益嚴重的問題。與此同時,傳統 12V 母線仍在使用,且 12V 負載和組件在可預見的未來也不會被取代。Vicor 的降壓模塊與雙向降壓轉換器提供靈活解決方案,為多種雙母線混合應用場景提供理想的技術支撐。

本文最初由 Mouser Electronics 發佈。

優化 DC-DC 轉換器穩定性:源阻抗效應的 AC 與瞬態模擬分析

探討如何通過頻域 AC 小訊號分析和時域瞬態分析來優化 DC‑DC 轉換器的穩定性

設計 48V 供電網路時需考慮並攻克的 15 項技術挑戰

為幫助您全面備戰 48V 系統遷移,在開啟您的第一個 48V 設計時,請考慮以下 15 項技術挑戰

ReVolt – 技術問答

ReVolt 正在解决好莱坞片場的排放問題,下一步將把可擕式 DC 電源應用於建築工地、應急回應事件等領域

ReVolt 如何利用 Vicor 技術實現電影拍攝的碳中和

Vicor 電源轉換器提供清潔、可移動的不間斷電源