Lev Slutskiy, Business Development Manager High Performance Computing, EMEA

Edge computing is essential to realizing the full potential of artificial intelligence (AI), machine learning and internet of things (IoT). These technologies are being infused into every corner of our lives—autonomous driving, smart buildings, robotics, supply chain management and healthcare. To deliver on the promise of these smart technologies, faster computation and data transfer speeds are needed closer to smart devices, closer to “the edge.” HIRO, a Dutch entrepreneurial technology company, leverages modular power in scalable micro data centers for low latency applications, powered by DCM power modules from Vicor.

Edge computing is the invisible driver to this smart world, designed to make our lives easier and better in ways we never imagined. But what does it look like, and what’s driving it? Just as importantly, how do you reliably and efficiently power the edge?

HIRO, a Dutch entrepreneurial technology company, develops innovative high-performance, reliable edge infrastructures (hardware and software) that can deliver intelligent edge as a service for industrial and other end users. They have seen steadily-increasing demand for intelligent edge services that can run autonomously and support analysis of large data streams in real time for multiple tenants (groups of users sharing access to a software instance), while safely sharing the analysis results across multiple locations.

Why edge computing?

Edge computing serves as a faster (middle layer) relay for data to enable mission critical, real time responses in devices. Edge computing can dramatically boost services and applications by supporting AI natively, instead of relying on AI in the cloud. Edge computing technologies integrate the limited memory, storage and computation of nodes that are closer to where data are generated into the cloud architecture. They facilitate intelligent decisions on when to move computation from the edge to the cloud, while allowing for the network capabilities as well as the security and sensitivity of data.

This industry-preferred approach enables long-awaited developments, including Factory 4.0 and smart manufacturing, 5G, internet of things (IoT), self-driving vehicles, smart cities, smart hospitals, robotics, machine vision and others.

The success of edge computing depends on the availability of suitable hardware; systems that can economically provide the necessary processing speed and power, while being able to survive in the less-regulated and more unpredictable environments encountered away from the conventional data center.

The edge computing hardware must comprise compact, energy-efficient solutions that can be widely deployed, even in space-constrained and harsh environments, to locate computing closer to sensors and other data sources. The hardware includes the power delivery networks and conventional bulky low-voltage power solutions are not able to support the increasing power density and small form factors at the edge and are a major bottleneck for edge computing innovation.

An efficient and scalable solution

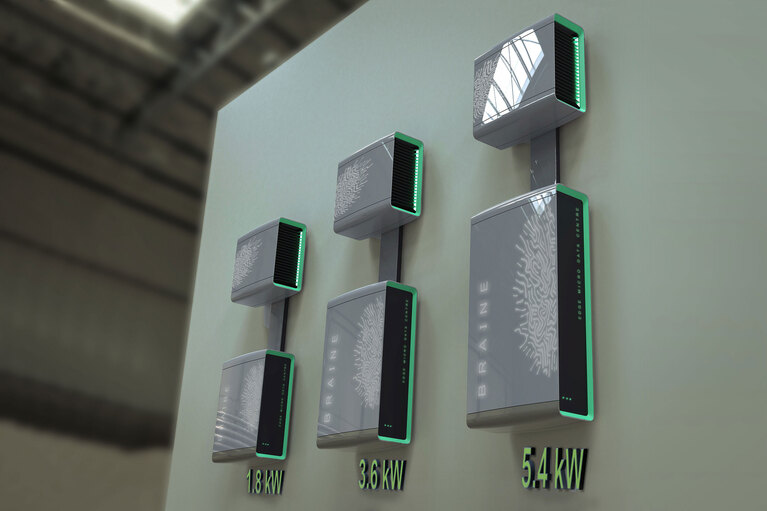

HIRO makes Edge Micro Data Center (EMDC) – a highly scalable, compact, edge computing resource that can thrive outside in harsh environments. It can integrate any type and quantity of CPUs, GPUs, FPGAs and NVMe® (Non-Volatile Memory Express) media into platforms from 1.5kW shoe boxes to 500kW containerized edge installations. Fully solid-state and modular, these platforms require little maintenance and no energy for cooling. Heat can be dissipated via a fan-supported dry-cooler (see Figure 1) or a completely passive dry-cooler making the EMDC passive. The high-bandwidth, dual-switching fabric (PCIe, Ethernet) and scalable design gives customers complete freedom to compose the EMDC with any combination or quantity of CPUs, accelerators, and flash storage.

Figure 1: Micro Data Centre examples EMDC8 (1.5kW), EMDC16 (3kW), and EMDC24 (4.5kW).

Real applications with community impact

HIRO has a special commitment to building an edge infrastructure distributed across academic hospitals in Europe to support large data set and even real time procedures. Hospitals rely on large data sets that go beyond their own data sets to train AI models that can help detect and cure cardiovascular diseases, cancer, tumors, and other complex disorders. Additionally some hospitals are leveraging edge computing in the operating rooms. Intra-operative functional Ultrasound (IOfUS) has the potential of improving surgical effectiveness and patient safety while expanding the surgeon’s view by directly visualizing neural structures and supporting the surgical procedure (see Figure 2). IOfUS is the most affordable and least invasive modality for intra-operative imaging of the brain. Ultrasound is portable, flexible and provides real time intra-operative imaging whenever needed during the procedure. The progress of surgery can therefore be closely monitored without major delays or interruptions in the workflow by employing edge micro data centers.

HIRO is also working on the €16 million BRAINE project, which received €8.5 million EU’s ECSEL Joint Undertaking funding. Four test-bed locations across the EU – two in the Netherlands, one in Italy, and one development platform in Hungary – will serve several test applications addressing Smart City, Smart Hospital, Smart Manufacturing and Robotics, and Smart Supply Chain.

Figure 2: Intra-operative functional Ultrasound improves surgical effectiveness and patient safety while expanding a surgeon’s view by directly visualizing neural structures and supporting the surgical procedure.

High power density leads to cost efficiency

HIRO is able to build highly compact EMDCs and solve the technical bottlenecks of signal integrity over shorter electrical traces, highly compact and efficient power conversion and energy efficient cooling and engineering. In addition to being device-agnostic, flexible and scalable, the EMDC is high-performing and saves at least 40% on energy consumption compared to legacy systems. Its solid-state design (no moving parts) improves availability and reduces callout incidence – particularly valuable for edge installations in remote or unattended locations.

Highly compact and efficient power conversion is achieved by designing hardware running from 48VDC power distribution, instead of 12VDC (see Figure 3). The higher voltage reduces I2R losses across the power delivery network (PDN). While 48VDC distribution is common in telecoms and industry, it is only now beginning to find acceptance in data center and associated edge environments.

Figure 3: Vicor DCM 48VDC – 12VDC power modules: contributing to HIRO energy-efficient EMDC designs.

Vicor high-density, high-efficiency power modules contribute to HIRO’s solid-state, thermally adept, compact, energy-efficient EMDC designs. Legacy solutions using standard COM Express modules (computer-on-module), for example, draw 150W per card. This equates to approximately 3kW within one 3U chassis. The ability to handle this high-density power conversion is unique to Vicor in the market.

HIRO has been using Vicor DCM modules for 48-to-12V conversion. In their view, the Vicor power modules, with their flexible cooling options, offer world-leading volumetric power density. The flexibility lends itself to renewable energy opportunities. The HIRO EMDCs will eventually be able to be positioned by a solar farm or wind farm and connect safely and reliably into the renewable energy supply.

The first step for HIRO is to enable 48V systems, while providing infrastructure for legacy 12V designs. Next will come support for chips like PGAs, converting down from 48V to around 1V at the point-of-load.

In the HIRO system, Vicor owns the DC power conversion from the chip level all the way up to edge data center level. This discrete solutions require considerable power system design effort while off-the-shelf designs are bulky and lack the flexibility needed to adapt to different environments.

Vicor modules offer reliability, high power density, flexible cooling, high conversion efficiency and a wide choice of products for different DC voltages and power requirements. These products assist HIRO in designing compact, efficient, solid state EMDCs that can survive outside a conventional, environmentally managed data center building.

Bringing Europe closer to the edge

The continued mobilization of our smart, connected world is an enormous undertaking. Edge computing is the critical bridge to enable faster computing and realizing what new ideas are possible. HIRO, Vicor and PCB Design Ltd. are three important drivers of this movement, working together to push the technological boundaries. Today their partnership will lead to impactful enhancements in the areas of Smart City, Smart Hospital, Smart Manufacturing and Robotics, and Smart Supply Chain. Tomorrow they will power the newest world-changing ideas.

Lev Slutskiy joined Vicor in November 2012 working succeeding as Technical Sales Engineer, Regional Sales and Business Development Manager (Central/Eastern Europe). Since April 2020 Lev is responsible for the company business development in the area of high performance computing (HPC), data centres and artificial intelligence (AI) in the EMEA region. Prior to his position at Vicor, Lev was working over 30 years in the telecommunication industry in hardware/software development, technical sales, sales and product management.

Lev Slutskiy, Business Development Manager High Performance Computing, EMEA