15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

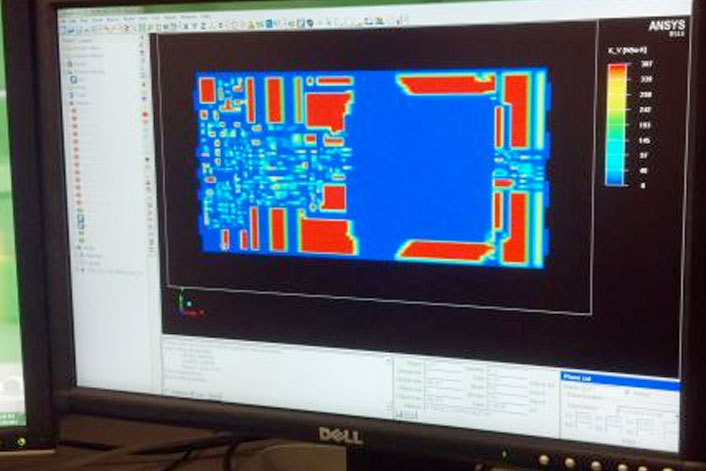

A key factor in designing high-density power devices is the thermal performance of the internal circuitry. Vicor maximizes efficiency to reduce the losses as far as possible when designing these devices. Even so, the heat generated by residual losses must be dissipated to avoid overheating, which has a direct impact on reliability.

As with the electrical test equipment, much of the all-important thermal testing equipment has been developed by the Vicor R&D department. The sophisticated wind tunnel system is one of the best available on the market, but the specialized thermal measurement equipment, product interfaces, specialized thermocouples and analysis systems are all designed and built in-house.

All test stations, and many non-production ATEs, include sensitive thermal cameras to identify potential hot-spots within the device to ensure the product does not exceed the thermal parameters under all load conditions in order to maximize performance, density and reliability. This detailed thermal analysis, extensive burn-in and the subsequent test data obtained is also used as a direct feed for Vicor comprehensive data sheets.

Vicor considers its high level of investment in design and testing essential to ensure that comprehensive, real-world data are obtained. Investment in development and tools is a top management priority within the company; every operation is equipped to do the job thoroughly. The company’s R&D budget is a high priority and is funded generously as part of the company’s strategy to invest in innovation.

In addition to the accuracy and detail of product datasheets, the investment also means that customers benefit from the many tools and resources available from Vicor. The Vicor suite of tools includes a web-based comprehensive solution selector that enables customers to select the best product for the application together with simulation to show exactly how the product behaves under all conditions. The Whiteboard helps customers configure their own optimized system solution, allowing them to simulate and evaluate performance at a power system level. Test date from real devices is used as the data feed for tools like the Whiteboard ensuring very high accuracy.

Wind tunnel used for thermal testing

Orthogonal thermal conductivity matrix representation of PCB trace and via geometry

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

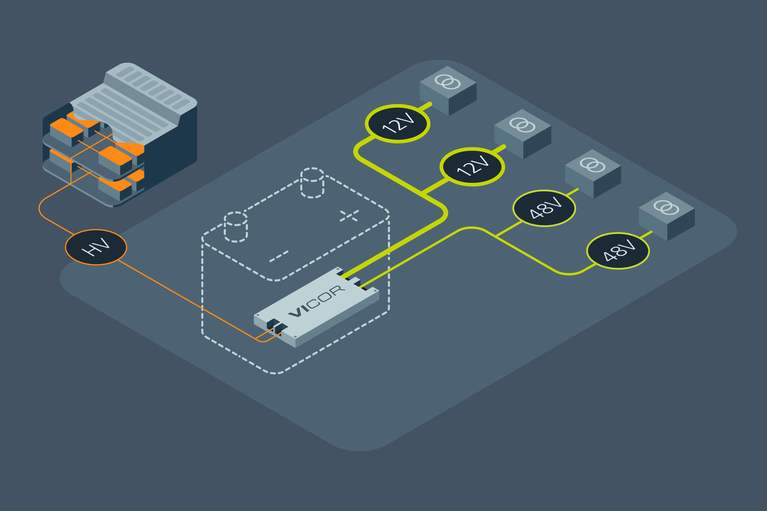

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

Power under pressure: Meeting the military’s surging energy demands

More capability (power) and compatibility are in demand for military power system designers. Learn how the Vicor SOSA Power Supply solves this problem